A model can help to expedite design technical queries during a large project.

Whereas large industrial engineering projects use 3D modelling as a means of expediting requirements capture, there is no equivalent for process automation.

During process automation project execution, numerous queries are generated by the programming team. These queries are usually answered by the client process automation team, or an engineering procurement contractor (EPC) on behalf of the client team. Sometimes the EPC merely manages the technical query process and has to chase up answers from the client. The whole process can be problematic, especially if different cultural boundaries, time-zones and different languages are evident. Generally there is an agreed query response process (like an internal SLA).

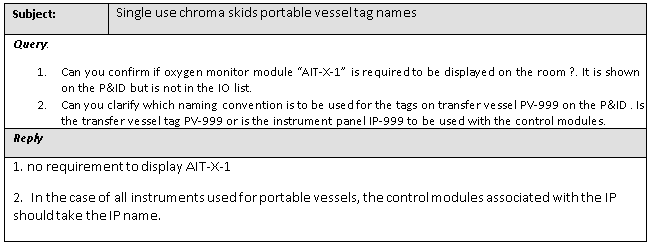

Here is a sample of a simple technical query relating to control system naming convention.

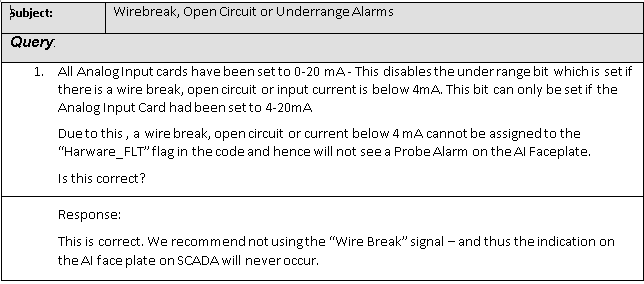

A model would have removed the need for this technical query. Here is a more complex technical query relating to process flow routing.

A model can make it much easier to prevent this error in the first place, during design. The ability to quickly ‘animate’ P&IDs in order to illustrate required functionality is a major use case for automation system modelling. Even the initial capturing of the question can be vastly sped up using a model to sketchup the query.

Of course, not every technical query can be alleviated using modelling.

Summary

A model that is easily accessible can help alleviate the number of technical queries in a modern industrial automation software environment.

See Spike in action or try it yourself, no sign up or login required.