Regardless of the IoT political atmospherics, Hannover Messe 2016 was once again the highlight of the year worldwide for every manner of innovation related to manufacturing.

This year saw the USA as country partners with Germany and made for fascinating discussion regarding the future of IoT. On the one hand, German industry, the pioneers of Industrie 4.0 have moved ahead with highly integrated supply chain manufacturing integration . This was evident on all the major stands; Web based ERP and manufacturing execution systems relaying their “lot size of 1” data to a subordinate layer of physical devices through OPCUA. All the factory floor devices now support OPCUA Server/client, with only supervisory control or ‘orchestration’ from the MES layer. To say this approach has simplified integration and reduced re-tooling costs leading to a more ‘Agile’ factory floor is an epic understatement.

On the other hand, the USA have so far gone a different route with the IIC . The IIC themselves were at pains to point out that even though Industrie4.0 RAMI reference architecture owns the industrie 4.0 space in Europe, it is not that different to the IIC reference architecture which has more influence in the US . The OPCUA standard does not yet have pub-sub transaction capability (though its AMQP campanion standard release and implementation is imminent) whereas the OMG / IIC group have the competing DDS technology already implemented. In addition , the heritage of OPCUA is the factory floor where security and reliability are the key use cases. This is not necessarily the case for other IoT verticals such as mobile health. Its likely that the different standards will dominate in different industry verticals with no ‘one size fits all’ solution.

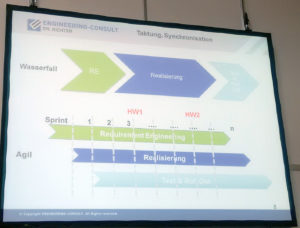

Elsewhere at the CAD / CAE forum, Agile engineering was the order of the day. The ‘Waterfall’ method of design project execution proceeded to

take a vindictive beating , lecture after lecture. The message was that ‘Waterfall’ projects are no longer capable at moving at the speed of current Industry 4.0 business. (Here at HAL Software, we get that!). Put simply, get a model or wireframe in front of your client as soon as you can, before you spend too much money, so that you know you are on the right track.

Model based engineering requirements capture is starting to gain mainstream adoption with the likes of VW Car manufacturers now starting to ask their suppliers to align with their model based requirements design (based on the PTC product Integrity)

We had a stimulating discussion with the Fraunhofer institute re micro- services architecture and its use as an enabling ecosystem for small companies to supply services to larger companies that cannot afford the cost of full blown IT systems. For example a documentation management system or Manufacturing execution system or quality management system. Check out Virtual Fort Knox wenn Sie Deutsche sprechen..

Siemens are the worlds biggest Automation company so it always pays to heed where they see the Automation market going and how they integrated the different aspects of design and manufacture in their TIA (totally integrated automation) platform. And according to Siemens , the future is virtual.

Virtual design, virtual commissioning, and even virtual programming of for example a robot arm. (So instead of teaching the robot movements in the real world, do it in the virtual 3D world then

auto generate this code for the real world robot). There was a lot of talk of a ‘digital twin’ and ‘closed loop manufacturing’ whereby design, test , and commissioning is pretty seamless. Here at HAL Software, we of course agree. We just differ when it comes to what technology to use. (Use an open system so that you are never tied to a specific vendor. )

Finally..

no Messe report would be complete with a…. table tennis playing robot!!! Seriously? Yep.

Comments are closed.