OPCUA Conference 2015 from the outside looking in..

Why is OPCUA so popular? It sits on ethernet, is a secure client-server object oriented way to expose object data. And now it is open source too.

Spike is based on OPCUA and exposes a generic set of data semantics i.e. objects from some well known process automation standards; S88 & S95. As its at the core of our product, its important to stay abreast of whats happening to the the standard in terms of support, global acceptance , and growth in scope. There are a lot of competing IoT technologies presently vying for attention. To that end, we went to Paris to discuss OPCUA growth curve and here’s the executive summary;

All manufacturing Automation is beginning to go OPCUA. Hopefully the OPC foundation can scale with the increased interest; its a tough ask. The new board members will help in that regard. They have open-sourced their core libraries so that will certainly help (files are on github), but an avalanche of roll-your-own OPCUA devices is likely.

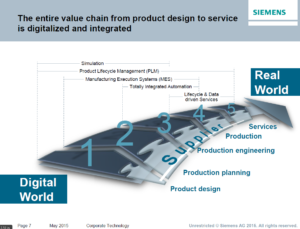

A Siemens keynote speech from Marquart Franz summarised the present state of flux in manufacturing: Customers are demanding Shorter innovation cycles, individualised mass production and

improved efficiency. He emphasised the Siemens product suite which spans end to end engineering. This is of course great if you have decided already to be ‘locked-in’ to Siemens hardware and software. But what if you have not yet decided about your target platform? Hal Software feel that a prototyping /modelling capability that is hardware and software system independent has a place in process engineering development.

A myriad of industrial consortia are now embarking on their own industry segment-specific data semantic standards, exposed as extended child classes of the base OPCUA object type. The packaging industry, the plastics processing industry and the robotics industry to name just a few, all have their own unique requirements. Some companies want the ability to have OPCUA devices pop up on a grid and then be automatically recognised by the supervisory system. Left-field requests from mobile phone, smart grid, automated traffic management, and consumer technology IoT companies are coming in thick and fast with their own unique use cases. One size rarely fits all. What happens when it becomes a wish list for the fixes for everything that competing IoT technologies are not?! Does it become too cumbersome? OPCUA might just be the best possible chance that the world has at connecting everything industrial, to the internet in a secure fashion. Paradigm tech and financial shift in the making..

So the OPCUA board have sensibly opted for the concept of companion standards to be generated by the various industry working groups, along with the consolidation of a very few use cases into an OPCUA code standard update. I don’t envy their task. OPCUA Board member, and highly regarded subject matter expert Matthias Damm quite possibly has the toughest IoT job in the world right now.

Near future OPCUA Roadmap

Publisher-Subscriber implementation.

Think of this as cloud scaling capability. It is an implementation whereby millions of clients can all subscribe, indirectly via an AMQP broker to the same server generated event. It is more economic on resources and more scalable from a cloud perspective.

TSN (Time sensitive networking) Ethernet.

For 30 years we have been painfully programming field busses based on token passing prototcols bit by excrutiating bit, because we have always known ethernet is not deterministic. Finally, because some major industry players want to expose an object oriented data model (OPCUA) over a deterministic prototcol (TSN ethernet) we now have a real effort underway to provide deterministic ethernet. Companies such as Kuka (Robotics), Audi and National instruments are all on board to create a new IEEE ethernet standard. Its not a new idea; profinet, ethernet/ip, ethercat etc are all proprietary deterministic ethernet. They just don’t mesh well with opcua presently.

Out with the old, in with the new..

A corollary to this is that peer to peer deterministic ethernet communications using OPCUA is in development right now. Its likely that this cheaper (ethernet), faster (Gbps), better (encrypted secure object oriented communications) and easier to use (if you are a high level object oriented or OOP programmer) tech will supplant older field bus technologies. Not least because there are more high level IoT OOP programmers than older field bus automation engineers – so the programmer skills barrier-to- entry for the automation discipline, will be lowered.

It looks like internet development lifecycles are seeping in to the manufacturing landscape.

Ad-Hoc discovery / Dynamic DNS / Global discovery service (GDS)

There is a use case for self configuring plug and play OPCUA smart devices. This is being driven by smart grids and smart-traffic grids for example. (This serves no purpose on a factory floor where every device is stationary. However it is relevant to mobile devices). GE already have a global discovery service product that takes the pain out of certificate management, and this was presented at the show.

AutoID companion specification working group

This companion group outlines how every OPCUA device can have a unique ID. In addition it defines a number of types for e.g. barcode scanner. This was of special interest to HAL Software as we provide a barcode scanner type in our S95 model.

Microsoft universal windows platform, Azure IoT and OPCUA

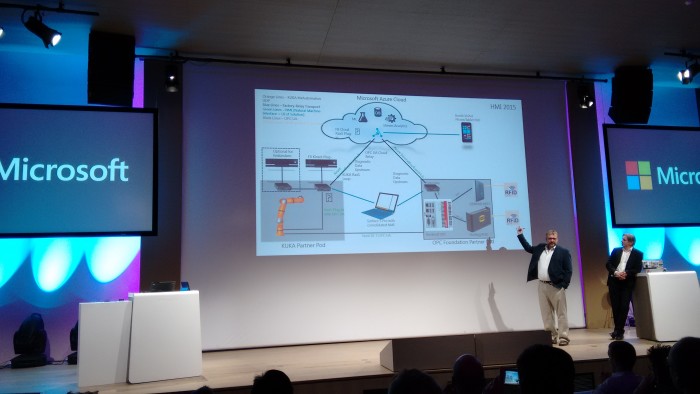

and Erich Barnstedt (Principle Software Engineering Lead, Windows IoT) outlines Azure IoT

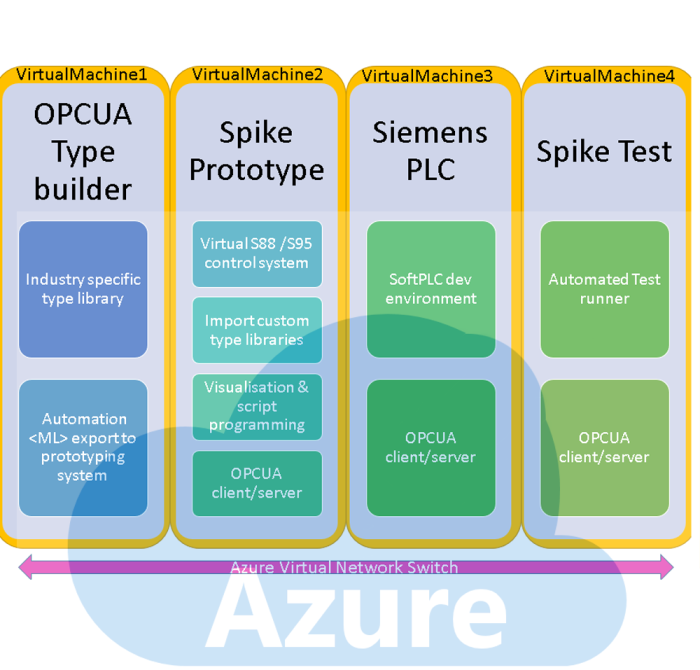

Speaking of .NET, and .NET 5 in particular, running on windows 10 universal windows platform, Clemens Vasters, Principal Software Engineering Lead for Windows IoT , gave a blazing performance as he outlined Microsofts Sensor to Cloud Azure / IoT strategy. This was of particular interest to HAL Software as our OPCUA based prototyping application is indeed Azure based. It is not however a brokered OPCUA publisher subscriber mechanism running on Azure ‘fabric’ but that’s where OPCUA on cloud is headed and there are plenty of use cases. (Any geographically dispersed plant for e.g. a water distribution system is a valid use case)

It was the implementation of the Azure Event hub service bus, together with Kuka , for Hannover 2015 demo, that formed the basis of the new OPCUA pub-sub working group.

In what turned out to be the highlight of the show, Clemens provided deep insight into some Microsoft IoT Azure strategy guiding principles (All other things being equal between 2 competing technologies, the least complex, most loosely coupled tech wins out) .

Of course, Microsoft want to sell their cloud, so some scare mongering regarding lack of internal security infrastructure on the factory floor (no field busses are encrypted and there is no authentication or authorisation infrastructure) need to be taken with a pinch of salt – unless of course you are opening up factory floor to internet level threats, in which case you have to implement a new security infrastructure. Microsoft have also joined competing IoT standards group AllJoyn, but their position is that OPCUA ‘owns’ the industrial factory floor, with home automation still being an open playing field for competing IoT tech.

Rise of the machines? – No longer just the realm of Hollywood.

There was another great presentation from Heinrich Munz of Kuka. My impression of their take on Industrie 4.0 is; connect the ‘soon-to-be’ autonomously organising robots to each other via real-time ethernet, and to the cloud via internet, with both paths using OPCUA for communication.

Mr Munz outlined an enormous OPCUA implementation from the motor industry with every node on the robotics network exposing its data via OPCUA. (Here at HAL Software, we are wondering when Isaac Asimov’s three laws of robotics become the next OPCUA working group…)

AutomationML

IF OPCUA is ‘how’ to communicate objects between 2 systems, then the AutomationML can be thought of as ‘What’ to communicate. One really nice aspect of Automation ML is the ability to implement ‘role classes’ on a type. This is the equivalent to implementing an interface on a type in C#or Java (and very powerful)

The AutomationML talk was perhaps a little disappointing from HAL Software perspective as this standard is a superset of CAEX IEC62424, Geometry and kinematic format COLLADA, and logic format PLCopen.

As Spike is a prototyping application used for generating software design specifications, there is not yet a perceived use case for generating physical location documents for system hardware.(This info is already in 3D CAD files). And that is what AutomationML is good at. We will of course provide the ability to export physical model in PLCOpen XML format. (Watch this space..)

How secure is OPCUA from hacking threats..really?

We are about to find out. The German government sponsored security organisation BSI is trying to break / hack OPCUA C implementation as we speak, and their results will be published publically later this year. BSI have published a 4500 page document on critical infrastucture guidelines and OPCUA will be reviewed against this document. Interestingly, a show of hands noted that most people have implemented the C/C++ OPCUA stack, with .NET stack being second, followed by Java.

Show Verdict?

Overall, nothing has changed since Hannover 2015 other than the fact that the pace of adoption is quickening. The Germany Industrie 4.0 government initiative is serving as a template for Government IoT- based initiatives the world over. OPCUA, as a result of some new backing, is manoeuvring into an IT friendly Industrial IoT technology.

Necessity is the mother of invention..

In response to dissatisfaction with heterogeneous systems being difficult and expensive to integrate, industrial internet consortia representing specific industry segments, are taking it upon themselves to develop the data model / data semantics for their specific industry (i.e. their own type library in OPCUA / Spike terms). These collaborations are becoming companion standards. Our very own product, Spike, provides a starting type library for the chemical and biopharmaceutical industry, but future versions will allow users to create their own type libraries.

Industry mammoths such as Kuka and Microsoft are bringing sizeable momentum to getting Cloud & real-time control use cases into the OPCUA development vision.

Want to get everything in your plant / cloud to communicate? Then wireframe out the semantic data model with the help of your suppliers.Implement it with OPCUA.

In other words , it, and attach the data specification to all subsequent tenders. Simple. Industry segments the world over are having to identify their data semantics up front in order to reduce costs by combining good front end engineering design with one of the oldest software engineering principles out there; ‘DRY’ or Don’t Repeat Yourself. HAL Software are experts in this field. Contact us for a demonstration of how to save project time and money using control and MES system prototyping.

Comments are closed.