Achema , Frankfurt 2018

Achema 2018 is where the worlds process engineering industry showcases its best gear and this year was no different. What a great show. Of particular interest to process automation engineers were the themes of Pharma 4.0 and Modular automation. Pharma 4.0 is mostly just marketing spin, but serialisation is the most obvious use case for fully integrated supply chain management and manufacturing. So where are all the solutions for the pain that is manufacturing IT and automation integration? Are the systems becoming more ‘open’ ? What does that mean anyway? How are industry suppliers addressing the constant project budget overruns and delays due to software not working or not being inter-operable with existing platforms . Well we went wandering through halls 9 and 11 to find out….

Pharma 4.0 , Pharma IoT, Namur Open Architecture

Though 5 years late to the industry 4.0 party, this year Pharma marketeers finally arrived. And no one really knows what it is. I was asked on more than one occasion, at different MES vendor sites ‘What is Pharma 4.0 to you?’. Lets call it as..full electronic batch records systems, serialisation with closer supply chain integration, batch size of one, and greater use of ‘open’ architecture and standards for now. Speaking of open architecture..

Bosch had a vial filling line on display with a Bosch Rexroth platform – one of the champions of ‘open’ platforms . This controller (It would be disingenuous to call it a PLC) was typical of the new modern controllers ; it has a built in opcua & web server primarily for OEE & maintenance use cases right out of the box. It also had a VPN stack onboard (the excellent OpenVPN) for secure remote access.The OPCUA server is presently just read only so on the face of it, not a cyberthreat vulnerability.

Namur Modular Automation

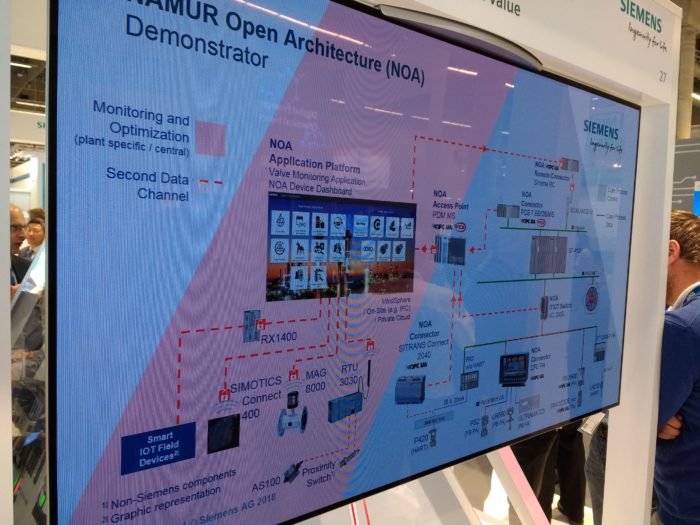

Both ABB and Siemens had similar process automation controllers on display. Controllers that have built in OPCUA, web server HTML5 visibility and secure cloud gateway capability right out of the box. The open architecture is starting to align , with conventional control busses (profinet etc ) for realtime IO control , and the likes of OPCUA server for non realtime (for now) data tweeting to cloud or any other subscribing client – good for fire and forget IoT. At the centre of this movement in Europe is the Namur NE148 standard. In the US, it is the open automation group. The Siemens take on Namur open architecture was on display. Basically there is a separate data channel for IoT or maintenance / OEE data that connects into the main process control architecture via NOA (Namur open architecture) access points. So non essential data does not interfere with essential plant control.

The Namur NE148 modular automation standard has been around a couple of years now. That standard was driven by the need to make modular process equipment skids easier to integrate from a control and MES perspective. While not quite ‘hijacked’ by the IoT brigade, Namur NOA seems to be NE148 with IoT..

The market is making software easier to use

Yokagawa have updated their flagship DCS to be more ISA-S88 batch aware, signalling a new drive to enter Batch driven markets such as pharmaceutical /biopharmaceutical industry.

Though known mainly for their Oil&Gas expertise, the latest Centum DCS offering has a comprehensive S88 style Batch model and even some basic MES functionality built in. The main strength of ISA-S88 design pattern is simply getting all the engineers on the same page, using the same terminology, earlier in a project. Its a communication tool as well as a software design pattern. So regardless of what proprietary platform an engineer has experience with, provided it implements ISA-S88 or ISA-S95 then a lot of the knowledge should be transferable between platforms. Heres hoping Emerson DeltaV gets some badly needed competition..

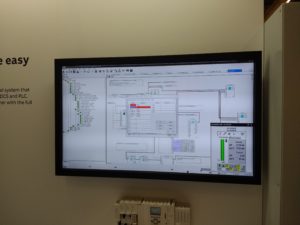

ABB have updated their Controlbuilder process controller software design platform and called it freelance DCS .It looks a lot like the CoDeSys development system (or Beckhoff twincat – they are all converging) with all the IEC61131-3 languages utilised, and the ability to create reuseable libraries of function blocks. It has a built in opc server and can apparently create web graphics too. It also auto generates the documentation, as well as the HMI faceplates for the controller itself.The controllers (starting with the AC700F ) can scale from a single controller for a skid right up to full DCS level, except no ISA-S88 so not for Batch. (A Batch add-on can be bought separately, to interface to a supervisory batch controller like 800xA Batch).

The updated controller is similar in concept to the new Emerson PK controller. Not a PLC, not a DCS, not even a PAC, more a hybrid controller like the Beckhoff Twincat embedded PC based controller platform. Unfortunately it doesnt qualify as an open platform. Unlike the ABB AC500 controller with Automation builder software platform, it doesnt have native OPCUA and theres no mention of PackML or PLCOpen support (for importing platform independent IEC61131-3 code) either.

…and Batch/MES simulation market starts to grow

You may not have heard of Spike , our S88 and S95 MES simulator, but Siemens and Adents have. And if nothing else, it is a sign of a burgeoning market in prototyping and modelling tools for the MES space.

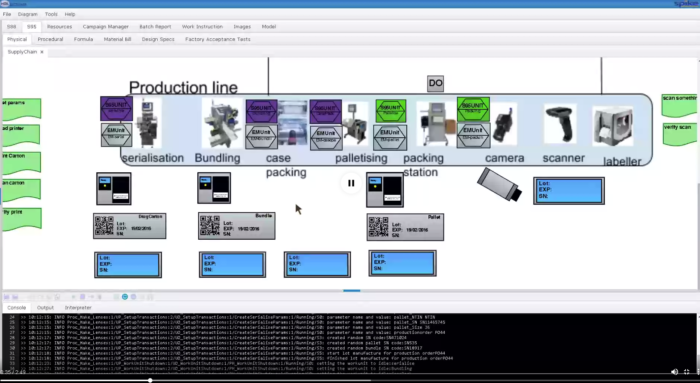

There was an MES simulator on the Siemens stand from the venture capital backed French MES company Adents. It was remarkably similar to our own Spike modelling software that we had presented at Achema in 2015. In fact the symbols were even identical! Printers, Cameras and even the demo was a copy of our own video that we released here (in 2016). I subsequently reached out to Adents to get some more info about this wonderful product but as yet, no response…

About the only difference I could see between Adents simulator and Spike was that we used a blister pack carton to represent the smallest lot of drugs in a serialisation model, but Adents used a bottle. Of course they still had the 2D barcode just like we had in 2015. We accept that you cannot patent a good idea so we will just consider it flattery that such a well funded company would copy such a small startup. After all,we based our serialisation model on Antares Autovision equipment and a Pfizer presentation given at an ISPE conference here in Ireland.

(Here is a link to our demo on the web since 2016 and here is a video of me presenting at a tradeshow in 2016 .)

Spike is available for demo via cloud anywhere anytime, just reach out. I dont think other MES simulators are so readily available for demonstration.

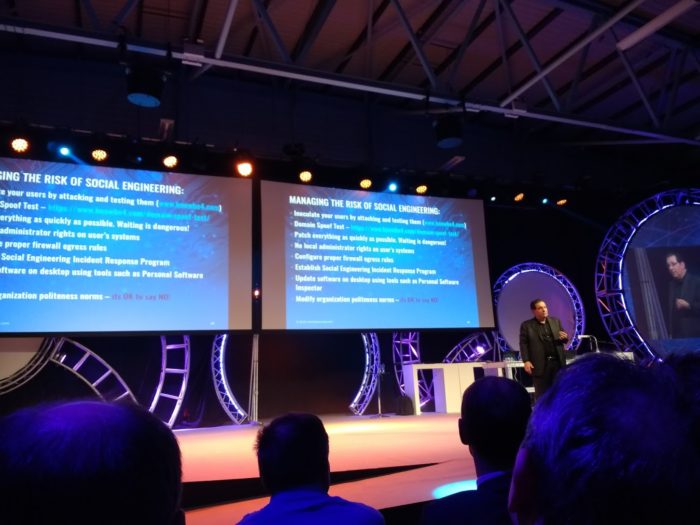

Manufacturing IT Cybersecurity developments

There are just so many talkers and so few doers in this space and plenty of them were at Achema . Do you need a cybersecurity engineer to harden your network against attack? you need to make sure that they are a real software developer /whitehat hacker first and network engineer /DevOps guy second. Ask to see their github page. If this elicits a ‘rabbit in the headlights’ response, then pass on the candidate.

Kevin Mitnick (he of FBI’s most wanted hacker fame) is the role model here. However, more recently , a large company (Kaspersky) put some resources against testing the security of the OPCUA standard. OPCUA is a bedrock of Industry 4.0. In the Kaspersky report here, Kaspersky took the OPCUA sample server reference source code (C language) , compiled it and found loads of issues. A bit unfair really, seeing as it was only a sample application, and companies do this all the time. (ie disable the more esoteric parts of software security to provide a getting started sample to get programmers up and running – self signed certificates and so on) . See the OPC foundation response here. Kaspersky did however find holes in commercial controllers that appeared to have just copied and pasted in the sample server code!! The commercial developers either disregarded OPCUA security functionality or rolled their own OPCUA servers , inadvertently giving OPCUA an undeserved bad name. Kaspersky credited this github OPCUA-Python library as being most helpful in their tests. (Of course it wasnt the first Python OPCUA library out there. HAL Software Spike has had built-in OPCUA-Python modules since 2015! )

Credit due to Kaspersky for doing this work . Its been 5 years of Industry4.0 and Cyberthreat scare mongering and this is the first time one of its bedrocks was properly challenged, as far as I can tell.

Agile design project execution development

Achema is a great opportunity to meet the frontline project managers for all size of engineering design houses. I especially enjoy asking the mainland European firms about conceptual design of big process engineering plants and then listening to the project design war stories. Big plant design and project execution is still largely ‘waterfall’ execution and not ‘Agile’. I always ask whether they think there is room to improve reqarding customer requirements capture – in particular for process automation systems. The answer is generally that there is no room to improve. That their internal systems have been optimised for 30 years and are lean. Some have highly integrated smartplant-style implementations whereby P&IDs and Bill of Materials and material data sheets all reside in the same database. Everyone gets why BIM (building information management) models are now so critical to capital projects but no one agrees that the same concept could equally be applied to PLC SCADA, DCS MES Process automation and manufacturing IT systems…at least not yet. Roll on Achema 2021 for the next update..

Comments are closed.